TIPS FROM INSIDE THE TRADE - hup! wall panels by Ultraframe

👋 By Russell Bridge, MD — Finesse Windows Ltd

As always - I’m here to share my honest opinion as to the pros and cons of innovations from inside our industry. I have no reason to automatically like or dislike the products I review - my sole intention is to provide an honest summary from my own perspective as Managing Director of a specialist glazing company so that homeowners may benefit from my research and consequent conclusions. My goal is to inform homeowners of the truths I find - based on real inside information that’s inaccessible to most outside of our trade. I’ll use a traditional Red (disagree) / Amber (somewhat agree) / Green (agree) method to try to boil everything down into understandable & meaningful summaries.

Overall, my hope is that homeowners may make better informed decisions on how to spend their hard-earned money after reading my tips.

hup! wall panels by Ultraframe

hup! panels are manufactured and supplied by Ultraframe - the recognised UK leader in conservatory roof systems. The hup! product has been around for a few years now & as such, most people in the double glazing industry should now be well aware of this concept. hup! is a form of ‘SIP’ which stands for structural insulated panel. SIPs are a well known & established method of wall construction which is widely used across the globe in light commercial building construction especially - with an emphasis on speed of installation and superior insulation.

Ultraframe make several claims in their on-line marketing material https://www.ultraframe-conservatories.co.uk/hup and advertise this concept under the banner of ‘the future of home extensions’. This is a bold claim from a market leader & as such this warrants further investigation.

Here are the top 6 benefits according to Ultraframe which I’d like to delve into further by taking each one in turn…

5x faster to build than traditional methods

The argument here is that in comparison to a traditional method of wall building (i.e. facing bricks & mortar on the outside skin with breeze block on the inside skin) the erection of a hup! panel will be 5 x faster. This is true to a degree but without a better understanding of the entire process you’re not really comparing like for like. The action of standing a hup! panel upright onto a base plate is certainly fast. The panels join together nicely & click into place forming a solid ‘I beam’ wall construction. However, once the panels are installed you then still have to apply the exterior faces in order to finish the walls properly. This involves fitting a breathable membrane, a further solid board to form a straight base layer to then apply either brick slips or a brick mesh / or apply render which then has to be left to dry out and then be painted. So overall it’s hard to argue that there’s a significant time saving element here. I certainly couldn’t endorse the assertion that it’s 5 x faster.

5x more energy efficient:

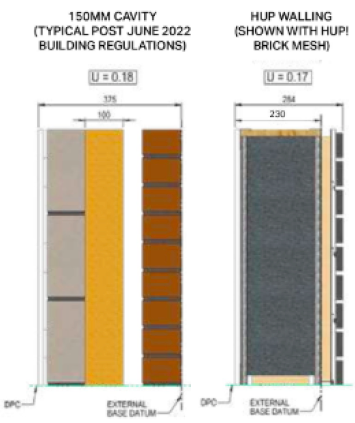

The assertion here is that hup! panels boast u-values between 0.12 and 0.17. This is extremely good because the lower the u-value the better performing the product in terms of heat retention. Current Building Regulations state that walls must be no worse than 0.18W/(m²K) therefore hup! meets and exceeds the requirements easily. Knowing how thorough Ultraframe have always been in their product testing I’d have little doubt that this is correct and I’m not doubting the science. Their hup! range carries all the necessary approvals to demonstrate that this product will pass any inspection from any Building Regulation office in any part of the UK.

By way of comparison, a traditionally built wall consisting of facing bricks outside / 115mm Kingspan insulation to fill the cavity / internal blocks and plasterboard to finish internally would achieve a u-value of approximately 0.14W/(m²K). This is therefore comparable to the hup! range performance. Therefore it’s hard to say that hup! is 5 x more energy efficient. However, it is possible to argue that hup! provides a great u-value at a significantly slimmer wall thickness.

The overall wall thickness required to achieve a similar u-value would be 340mm in a traditional wall versus an overall hup! wall thickness of just 275mm. (see diagrams attached) This is a significant reduction of approx 20%. This could be very beneficial for the homeowner as a smaller wall = a larger useable floor space internally. This is especially significant for a smaller building where every square inch matters even more.

One supplier, one project

Typically, a glazing company will have one or two teams of builders who dig foundations and then build conservatory walls. The well-established path is that once the builders have finished you then send in the installers who erect the windows & construct the roof. hup! brings a new & potentially large advantage to companies who have limited building labour resources. It’s feasible to see that with hup! you could potentially remove the need for builders to build walls & instead have the window & roof installers take care of the walls erection. Thereby removing an expensive and prohibitive bottleneck for some of the build.

However, you will still need a building team for the extensive base work. Depending on the exterior finish you will still need a renderer. You will still need a plasterer for the inside. Arguably the inclusion of hup! into your design might reduce the number of trades on site by a factor of one team. It’s a bit of a stretch to say that hup! = one team on site full stop.

Simply a better SIP compared to other SIPs:

When it comes to SIPs it’s clear that Ultraframe know their topic well. For the uninitiated it’s difficult to distinguish one SIP from any other - however, from a closer analysis of Ultraframe’s hup! wall product I believe it’s true to argue that this technology does provide a structurally superior, more thermally efficient, and certified alternative to traditional SIPs. The main differentiators being that it boasts:

- Unique structure: Unlike traditional SIPs (which rely on OSB boards bonded to insulation), this system uses steel-crimped composite panels that form strong I-beams with only a 2% timber fraction (vs. 15-20% in timber-framed houses).

- Superior Structural Performance: The design allows for large spans (8m+), making it more versatile than standard SIP panels, which suffer from insulation creep under constant loads.

- Optimised Thermal Efficiency: The system eliminates heat loss at key junctions (e.g., corners, window reveals, eaves, and ridges)

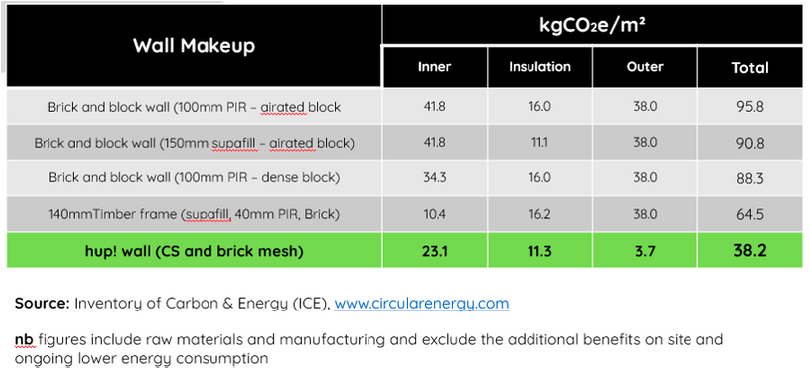

Kinder to the planet - 60% more carbon efficient

Hup! walls are significantly more carbon-efficient than traditional brick and block or timber frame walls, producing just 38.2 kgCO₂e/m²—less than half the emissions of standard brick and block constructions

(which range from 88.3 to 95.8 kgCO₂e/m²). This lower carbon footprint is achieved through reduced material use, lightweight construction, and optimised insulation, making hup! a more sustainable choice for eco-friendly building.

This table below demonstrates the difference clearly -this doesn’t take into account the ongoing savings that homeowners will benefit from in terms of lower heating bills - which is another important consideration.

Less waste & less mess on site

Yes, I fully agree with this. The process of building a conventional brick wall can be messy and wasteful. Sometimes you have bricks left over, sometimes it can be a messy process with mortar being mixed on site -especially if the weather is against us.

In Conculsion

My gut reaction to this product has always been quite a sceptical one but the more I’ve researched the more inclined I’ve become to recommend this product to anyone who is actively looking to incorporate a SIP structure into their build.

With all new innovations I’m minded to ask a series of ‘Why’ questions….. Why would a customer who is considering a glazed extension decide that this is a product they need in their home? Who is this product set to benefit? I still can’t shake the overall feeling that this is a product that’s been designed mainly for the benefit of installers as opposed to the end user - in this case the homeowner.

It’s important to understand that Ultraframe don’t sell directly to homeowners - they do sell to manufacturers and installers such as ourselves. They do have a great track record of excellent products and keep a keen eye on trends in the market place. But naturally their approach is understandably geared towards us as the installer. Therefore it appears that the hup! concept seems to be very much skewed towards what makes sense for an installer.

An extension / conservatory build can easily take a couple of months to complete. This is because there are many steps to go through and each one has to be done properly and often under the guidance of a Building Inspector. The nature of hup! panels being solid & not transparent means that most hup! builds will be subject to Building Regulation approval (as opposed to a traditional glazed conservatory which is exempt from these regulations). This means that often we will be required to dig down 2m to form the foundations which often means we are involving drains survey companies, Severn Trent approvals. The process is extensive and time consuming. The erection of the walls in isolation is a relatively small part of the overall equation. As outlined above, I’m not convinced that the time saving benefit on this small part of the job is actually quite as it’s being presented anyway.

Furthermore I’m not sold on the idea that homeowners are hell bent on saving a couple of days of time during the entire build. Speaking from our own experience - I can’t recall too many customers who have commented that a traditional brick building we made for them was great ‘but it took too long to build the brick walls’. I think that most clients appreciate that some things take time to be done properly and anything that is built to last 30+ years will take a few days rather than a few hours to build.

One of the main considerations that homeowners are always driven by is the basic aesthetics of the design. This shouldn’t be overlooked but it seems to be an angle that's noticeably lacking in Ultraframe’s marketing collateral. Put more simply - “Does hup! look nicer than the alternative?”

Bearing in mind that there’s a range of standard finishes it’s difficult to generalise here. But in my opinion -sometimes it looks great, other times it looks quite utilitarian.

Personally I’m a big fan of simple design, I like minimalist / industrial styles of architecture so I’m always taken by harsh angles and stark surfaces. However, there’s a fine line to be drawn and clearly it’s crucial to try to make the extension blend in with the original home. We have all seen properties that have been spoiled by extensions with bricks that don’t match, and with a limited range of brick finishes it’s easy to see that Hup might not be suitable in many circumstances.

I can foresee that in an attempt to steer clear of a brick mismatch many homeowners will opt for a contrast instead and opt for a rendered finish. This also carries a risk of jarring with the original building’s finish. In my honest opinion - I’d argue that hup! can sometimes look nicer (I do especially like the timber cedar cladding) but in the majority of cases it’s hard to argue that a traditionally built wall wouldn’t offer at least the same or better aesthetics.

Clearly, the hup! concept is actually much wider than just the introduction of SIP panels to form walls. To truly understand the whole philosophy that Ultraframe are trying to educate suppliers and consumers with and bring to market successfully -you have to consider the whole product range as one complete solution. This expanded product range includes the base, the walls and the roof. This is a much wider topic and not one for this article. I do understand the argument that if a customer invests in the whole hup! package then the efficiency savings do compound and therefore some of the benefits will start to multiply upwards significantly.

Overall, given all of the facts available to me I think our approach will be to facilitate hup! where a client is especially interested in any of the individual benefits that make a big difference to them & their project. But we won’t be advocating hup! as a standard item across the board. Ultraframe’s tag line that it’s ‘the future of home extensions’ may well be true in the medium to long term future. Given the significant carbon efficiency gains available especially, I certainly hope to see a future filled with more SIPs of all varieties. But in our immediate future we are continuing to offer the full range of traditional and modern solutions to suit our individual customer’s individual project.

For more tips and insights, visit www.finesse-windows.co.uk.